Project Brief:

This project was a continuation of the study of collaboration between non-human agents in a design project. We started the project by learning about the material of wood and its construction. We were given a specific design and asked to copy it exactly with a focus on craft. This recreated structure was the first module of the project. We then had to expand on the project by exploring the module when it was combined with other units. In groups of 3, we explored the collaboration of multiple units, which must function on their own as individual models, while becoming something new/more when together. This project really focused on modularity between the units.

individual Process:

Below is the cutting diagram that I made for the first unit. I also created a 3D-modeled diagram of the construction steps in Revit, which helped me to further understand how each of the pieces of this unit fit together, especially the differences in the forms between the mirrored top and bottom of the unit.

Below are various pictures of the construction process of my unit. We each had to make our individual unit in the wood shop, primarily using the table saw, but also the dado blade on the table saw and the band saw, then hand sand our piece, and put danish oil on to finish it. My group also used the 3D printers to make the pieces for our plant stand.

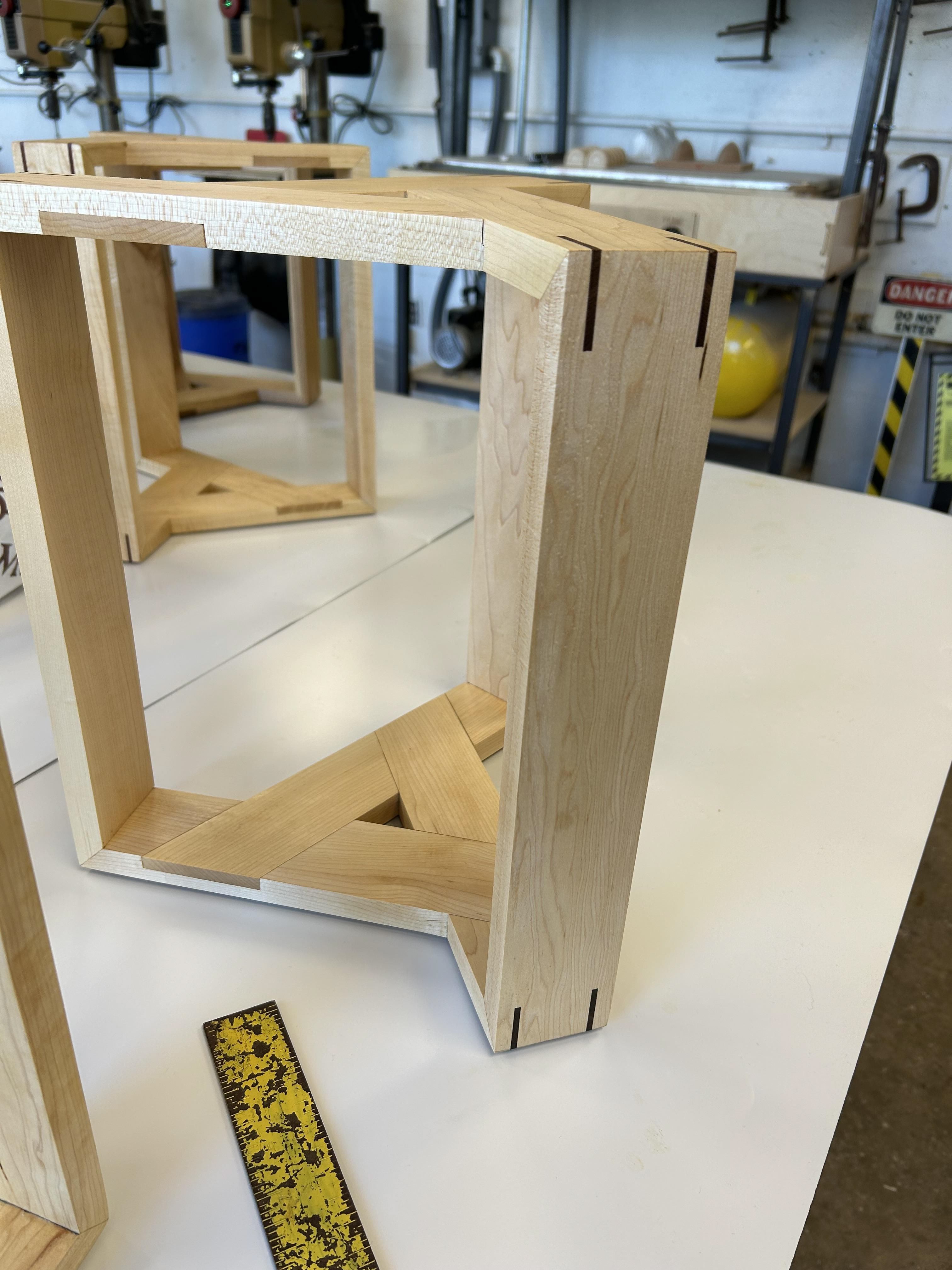

Final Individual Table Design:

Below are photos of my final unit. I chose to use walnut wood for the finger splines to emphasize the contrast of their dark tone with the light of the maple and to draw attention to their aesthetic qualities besides just the structural support they give.

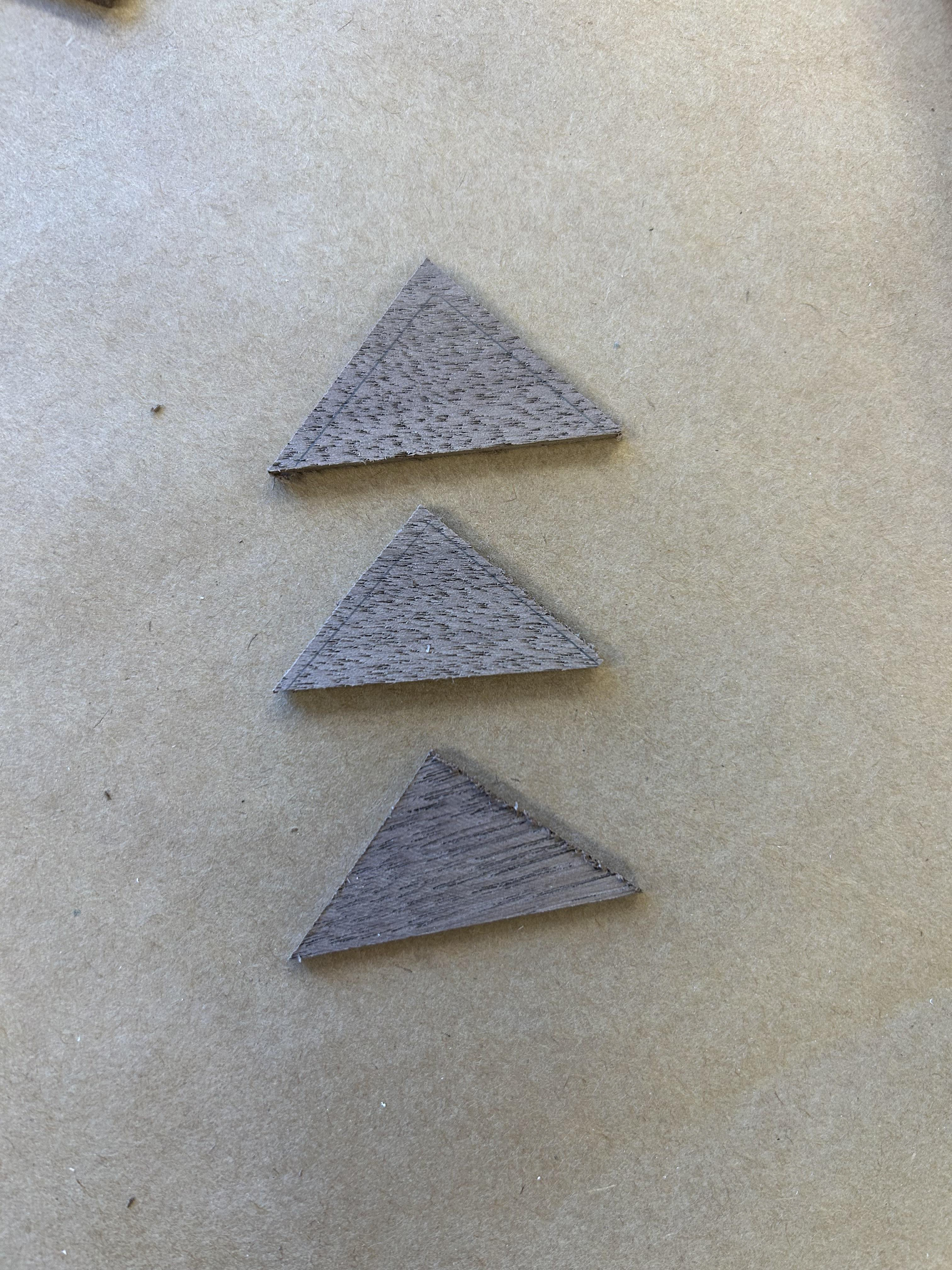

Above are all of my 3D printed pieces for my complete set of the Plant Rack, which is the photo to the right. My Plant Rack has a plant in the top pot with the hole and funnel where its water can drain into the pot below.

The Plant Rack Group Design:

Concept Statement:

Our final design was to create a stackable plant stand, The Plant Rack. The Plant Rack ensures that all plants placed on it are able to be watered in one action, and no water is wasted, as the drainage from the top plant will trickle down to those below. This stand could work with individual units alone, or with multiple interchangeable stands stacked together. The 3D-printed funnel pieces fit exactly within the negative triangular space at the top of each stand, and the printed pots fit snugly over the funnel piece. Therefore, no water can escape onto the wooden stand. The plant stand is also customizable per customer, as different types of wood can be used for the stand and the finger joints within the stand, as well as different shapes and colors of pots being able to be printed. We urge our users to be intentional when choosing plants for their Plant Rack. The top plant will receive much more water than the bottom plant, meaning it would make sense to choose a tropical plant for the top and a succulent for the bottom, especially if more than one Plant Rack is stacked.

We branded our project as the Plant Rack and created a logo for it. We also printed out these tags for each of our individual units which include the logo and a QR code on the back which provides access to each of our portfolios.

Below are photos of all three of my group's units being used together for the Plant Rack. My group wanted to put emphasis on how customizable each unit could be for each "customer" or person who would want to make their own. For example, I used a darker wood for my finger joints and one of my partners used a completely different wood for her whole table than the other two of us who used maple.